Does your sewing machine frustrate you? Here are some common problems and how you can quickly fix them.

It can be so frustrating when your machine just keeps giving up in between your sewing project. But before you take it to that expensive repairer, it may be worth the while to understand what could be causing the problem and try troubleshooting first. Below are a few examples of what could go wrong.

My thread keeps breaking

If your thread keeps cutting while sewing, try the following:

Change the thread: start by changing that thread to a different one and check if you still have the same issue. Sometimes, the quality of the thread is the problem.

Re-thread: try re-threading the upper thread and make sure that the presser foot is up when threading.

Delicate thread: some threads are delicate and meant for hand sewing and not machine sewing. Be sure you’re using the right thread for the project.

Tension adjustment: if the problem persists, lower the tension settings for the top thread.

Same thread texture at the top and bottom: it is important that the same quality of thread is used for both the bobbin and the top section of your machine

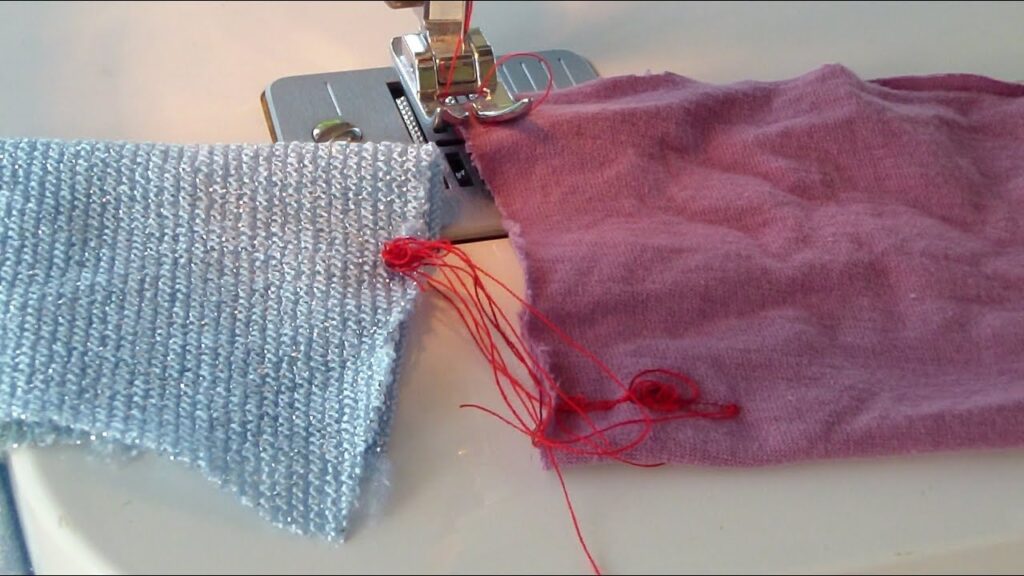

My threads are bunching up on the underside of the fabric

Start by cutting and freeing up all the bundled-up threads. Warning! Try not to pull it forcefully because that can damage both the fabric and the mechanism of your machine. When the threads are out, you can try the following:

Check machine’s manual: more often than not, newbies tend to thread wrongly. It is important you check the machine’s manual on how to properly thread. Ensure that your presser foot is up always when threading. The reason is because some machines lock the tension disks when the presser foot is down, this can make it impossible to thread the machine correctly.

Re-thread the bobbin: try rethreading the bobbin – in the alternative, switch the bobbin to another one.

Thread texture: ensure the thread used above and below are same textures. Tangle and knots will likely occur when there is a difference in the thread weight.

Adjust tension: Adjust and test your tension on a scrap of the same fabric you are working on. Tension adjustment is usually necessary when you switch from heavy to light fabrics and vice versa.

Bad Needle

A bad needle can cause breaking of thread and can bend during your sewing project. It is best practice to use a new needle for a new project. You will find that this simple task will save you some headache. Ensure you are using the correct needle for the fabric you are working on. For instance, you will need different types of needles when working on knits, jersey, leather, vinyl, denim etc. If your thread and needled keeps breaking, replace your needle with the correct one and make sure you fix it the way your manual instructs. If the problem persists, you may consider contacting an expert repairer because there might be other underlying problems.

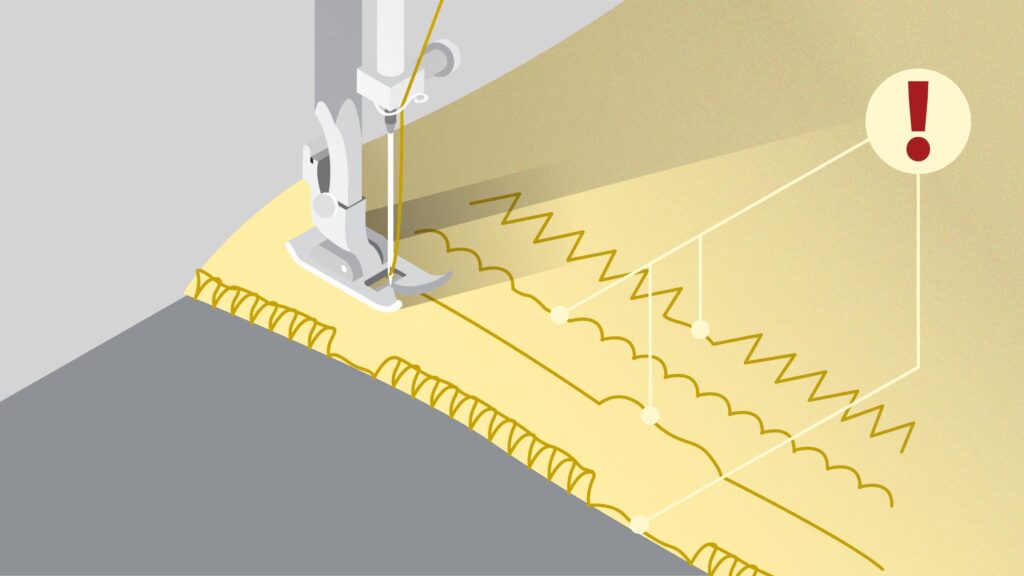

Machine is skipping stitches

This would usually occur when the top thread is not reaching the bobbin. This happens a whole lot and it can be extremely annoying. The starting point is to check your needle. Ensure it is properly fixed, not bent, and that you are using the right needle for the fabric. Consider re-threading both the top part and also the bobbin part.

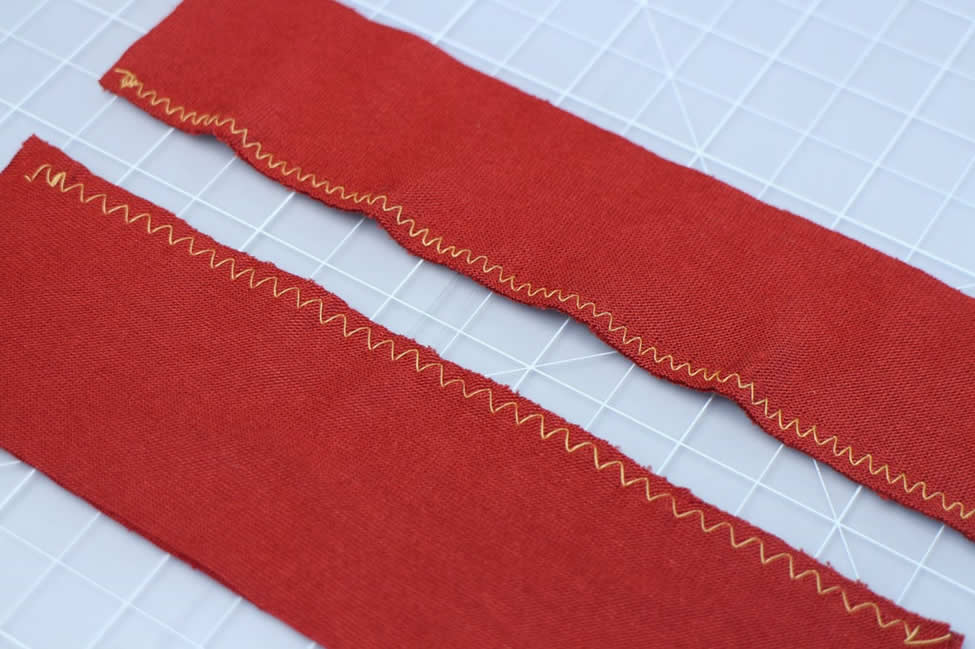

You are sewing a stretch fabric and the seams are wavy

Avoid pulling the fabric: you need to resist the temptation to pull as you sew. A wavy seam is more of a sewing technique issue mostly and it takes practice and patience to understand.

Position fabric correctly: it is important that you adjust the way that you are sewing, for instance, the fabric weight in itself can cause the stretch fabric to stretch while sewing. It is therefore important that you support the fabric to avoid dragging or pulling. Do not allow your fabric drape off the table while sewing.

Utilize the feed dogs properly: the feed dog on your machine has the sole purpose of helping to eliminate wavy seams. You need to let it do its job by not pulling your fabric to straighten while sewing.

Pin your project: more often than not, avoid rushing through the project without pinning. Resist this temptation. This is more so when you are working with stretch fabrics.

Switch to walking foot: a walking foot feeds the top and bottom layers of the fabric under the needle at the same time, and this helps in preventing distortion. This is an alternative option If the problem persists.

What happens when the sewing machine seizes and the wheel won’t move?

Usually, when starting your stitches, your machine needs some assistance by turning the handwheel. But sometimes, you may find that it does not move. If this happens, do not force it. There could be a few problems such as:

Fabric weight: if your fabric is too tough for the machine to handle, this could prevent the machine from moving. If you force it, you will damage your machine.

Needle: check that your needle is properly installed and that you are using the correct type of needle for the fabric. Double check that your needle is not bent. If unsure, replace the needle.

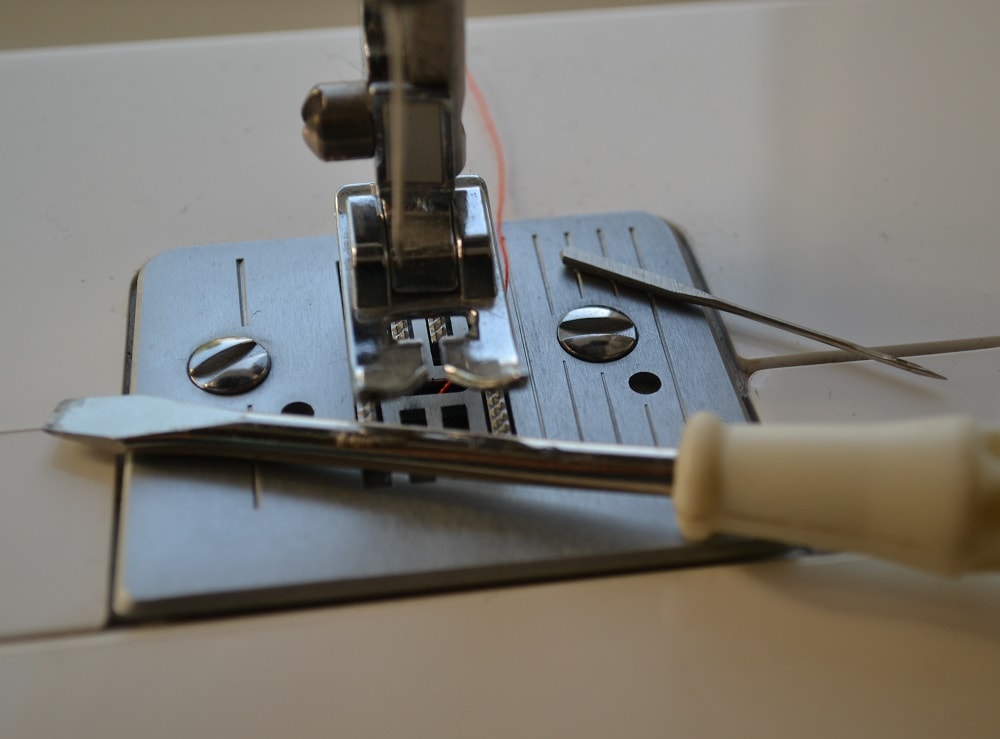

Clean it: check for any lint build-ups and clean them off because lint can prevent movement. Ensure you check your machine cleaning manual for maintenance tips.

My machine is making a strange noise

STOP! It may mean that lint or oil are collected on the hook or the needle bar. Do not continuously force sewing when you hear strange sounds. Most likely, good cleaning may be all that’s required but it may also require more. So, here’s what you should do – check your manual for the cleaning process and try to get dirt out of the way first. Also check that your bobbin is installed properly and not dangling, especially if your machine is the type that uses a bobbin case

What could be wrong? my machine is running but my needle is not moving

Check the winding mode for your bobbin. Sometimes, we wind and forget to return the switch back to the right position. This would usually happen with domestic sewing machines.

Bobbin Issues

For machines that have a bobbin case, check that your bobbin is not loose within its cage. When loose, it is difficult to maintain the correct tension. If you have to constantly adjust the tension of your bobbin thread, you can consider replacing the bobbin itself.

The thread in the needle comes off as soon as I start sewing

Always try to lift your needle to the highest point before threading. You can easily do this by hand rolling its wheels forward (and not backwards because that can tangle your threads). If you are working with a domestic machine, you may find that your machine has a lift up or lower function that will allow you raise or lower your needle automatically to the highest or lowest points.

I tried to backstitch but the threads are bunching up

When backstitching, try sewing some few stitches into your project before you backstitch at the start of your seams – backstitching at the very edge can cause bunching up of threads. Also, try backstitching before you get to the ultimate edge of the fabric and then sew straight to the end after that.

Fabric not feeding – could it be my feed dog?

Very likely! A dirty feed dog can cause this problem. Try cleaning the lint from your feed dog. Machines that have a drop-feed function tend to have built up lint around the feed dog. If your machine is an old one, you can consider changing your feed dog.

Don’t miss out on sewing tips and useful information. Subscribe to our newsletter. This way you can also benefit from special promotions.